21St May2019

Material Automation (Thailand) Co., Ltd.

Material Automation (Thailand) Co., Ltd. under Canon Marketing Japan Inc. (Main Office: Bangkok, Thailand, President & CEO: Mr. Makoto Yoshida, MAT hereinafter) and Thai Takasago Co., Ltd., Thai subsidiary of Takasago Thermal Engineering Co., Ltd. (Head Office: Samutprakarn, Thailand; Managing Director: Mr. Takehisa Muraki, TTC hereinafter) entered into a Memorandum of Understanding (Moll) for their loT Project .

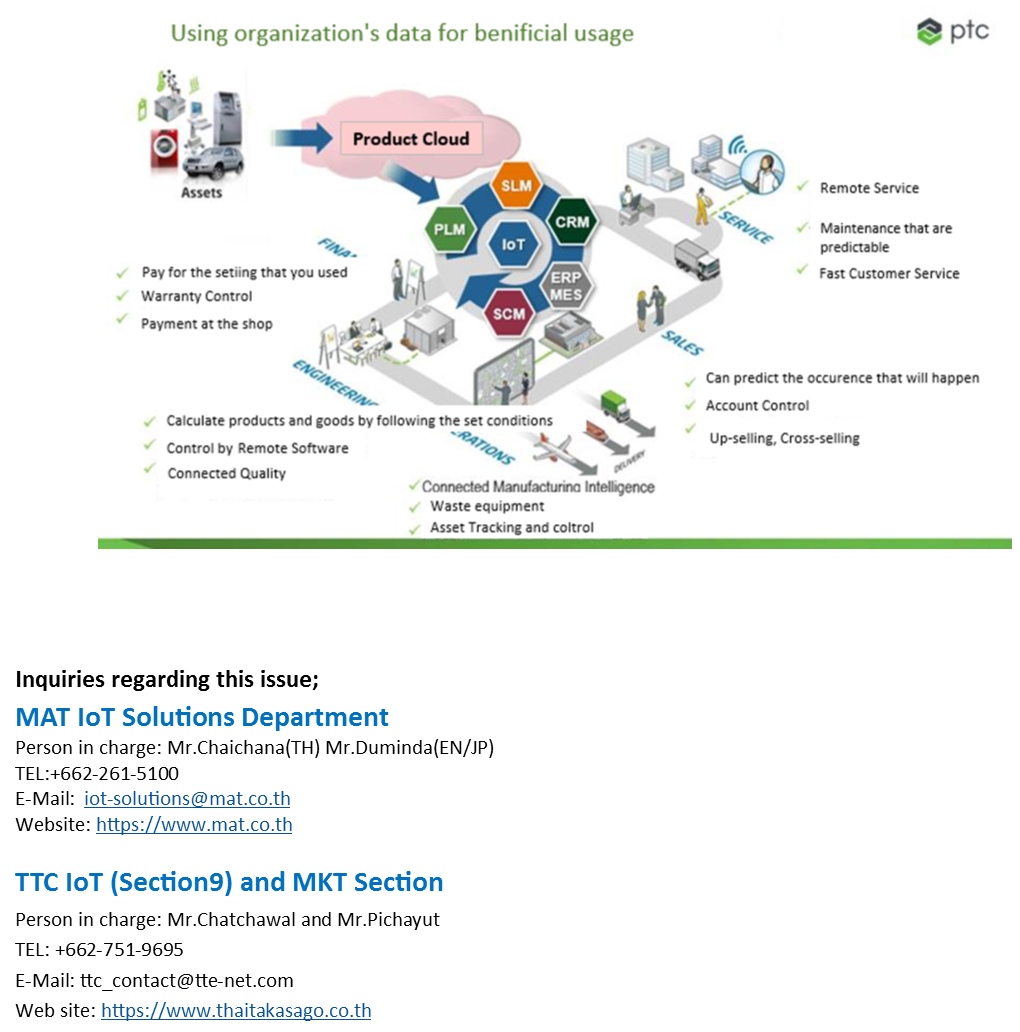

TCC and MAT work together to combine “ThingWorx,” an Internet of things (loT) platform system developed by PTC, and optimized sensors in order to automatically collect data from service facilities of clients’ factories and buildings such as air conditioning and pumps, and these data will be managed within a crowd data system. By displaying the operation status on various dashboards, the effectiveness of damage prediction/preventive maintenance will increase.

Enhancing synergy between TTC’s long-time experience in general facilities construction business with advanced air conditioning technology and MAT’s impressive past achievements in Thailand’s IT solution arena, we are confident that our partnership can provide new values to existing clients while attaining new customers by differentiating our services from competitors.

The importance of new technologies such as loT and artificial intelligence (Al) has been strongly recognized in the global market. In Thailand, due to the gradual rising labor costs and lack of workers caused by declining birthrate/aging population; lowing energy usage, less labor and lowing costs have become necessary. Therefore, utilizing loT into managing facility and equipment has become an important consideration for many companies.

Due to these circumstances, this partnership between TTC and MAT aims to effectively prevent customers’ facilities and equipment from any malfunctions through visualizing critical operational data. By finding any problems in facility and equipment in advance, we can also increase operational efficiency. Finally, by making facilities remote operational, we can achieve energy conservation at the highest level. Our service will launch in the beginning of 2nd half of 2019, which we aim to provide sustainable monitoring service to many clients all over Thailand within this year.

The following is an article published in NewsClip

https://translate.google.co.jp/translate?hl=&sl=ja&tl=en&u=http%3A%2F%2Fwww.newsclip.be%2Farticle%2F2019%2F05%2F21%2F39779.html